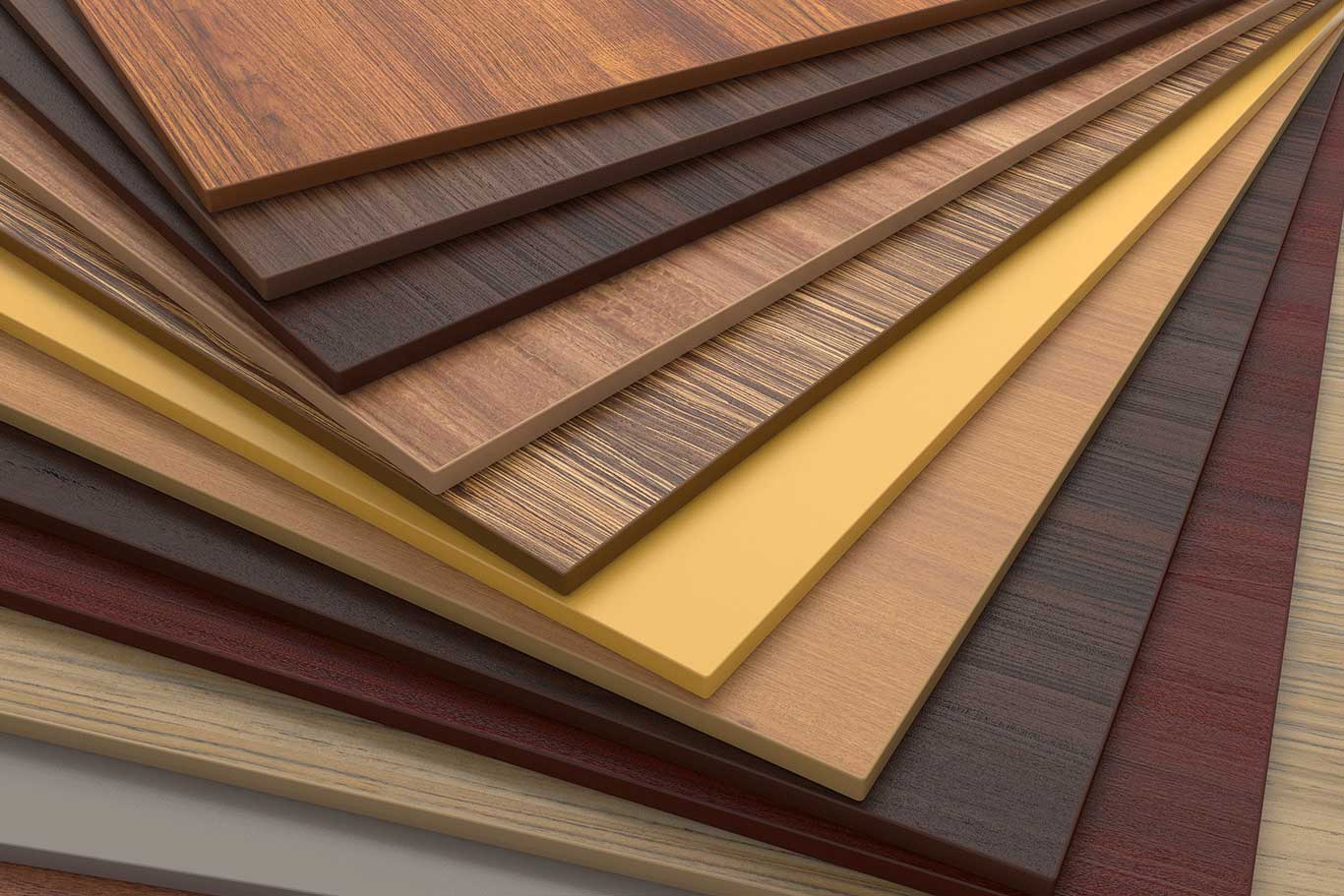

Melamine Faced Chipboard

Melamine faced chipboards are products that result from pressing the chipboard with the impregnated decorative paper under a certain temperature and pressure for a certain period of time. MFC offers various usage possibilities for furniture, office and interior among 13 different surfaces on around 200 decors that produced in different thicknesses and sizes.

Applicable Areas

Furniture Industry: Bedrooms, Young Rooms, Kitchen, Dining Rooms, Children’s Rooms, Office, Closets, Cloakrooms, TV Units, Bath Cabinets, Dideboards, Kitchen Tables, Chairs, Coat Stands, Television Tables, Headboards, Bed Base, Dresser, Counters, Meeting Tables.

Construction Material: Seperators, Amusement Places, Library, Bureau, Factory, Upper Table of the White Appliances, Studio, Boutiques, Banks, Elevator, Fairs, Medilcal Offices, Educational Fields, Yachts and Boats, Hotels

Surfaces

Mirror Shine(HG), Smooth flat(P), Wood Structure(AY), Oak Structure(MS), Sand texture(KB), Thin Sand Texture(B), Natural(DS), Short Cross-Section(S), Ash Tree Structure(D), Wood Line(WL), Silk mat(SM), Textile Surface(TY), Break Wood(BW).